Control system migrations at the push of a button

Developed by CIMA+, TEMPUS is the only tool on the market that allows you to replace aging control systems completely online, with zero interruption to your plant’s production – saving you time and money.

What is TEMPUS?

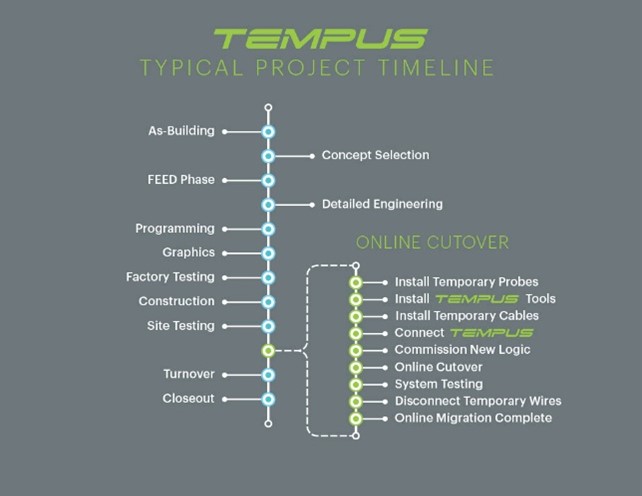

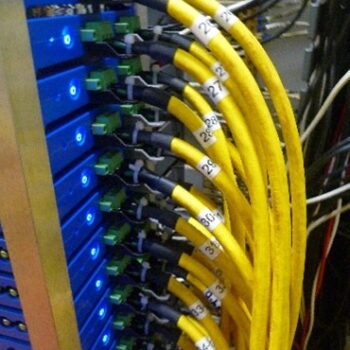

TEMPUS is a UL™ certified, temporary hardware installation that facilitates all the wiring from one control system to another, without disrupting the signals. Once the new control system has been fully tested, the control is switched to the new control system at the press of a button. As soon as the cutover is complete, the tool is removed, leaving a new and well-organized control system with no legacy equipment remaining.

Combined with the expertise of the CIMA+ automation engineering team, TEMPUS eliminates shutdowns and simplifies the entire project. Risks and unknown factors surrounding the migration process are significantly reduced. This allows our team to carry out the whole project from concept to completion, including engineering, programming, procurement, construction, migration and commissioning, without impacting production.

The TEMPUS advantages:

- Elimination of plant shutdowns

- Online commissioning and testing

- Elimination of I/O signal disruption

- Fail-safe operation

- Unlimited number of I/O signals

- Significant reduction in project costs

- Added flexibility for designing and commissioning

- Migration from/to any platform -vendor independent

- Uses physical signals rather than protocols or software emulation

- Supports all conventional I/O types

David Findlay, P.Tech. (Eng).

Senior Project Manager - Partner

Implement Tempus

Meet David Findlay, the lead behind TEMPUS

David is a Professional Technologist (P.Tech. Eng.) in the disciplines of electrical engineering and control system design. His focus has been on control system migrations of all kinds, including our in-house technology for online migrations. As a Partner at CIMA+, David is responsible for the Instrumentation and Controls department in Alberta. He has worked in the Automation industry for over 17 years on a wide range of projects.

email: TEMPUS@cima.ca

Feature Projects

RADU Honeywell HPM to DeltaV Migration

The versatility of TEMPUS allowed us to adapt the technology for various environments. TEMPUS is typically used in rack rooms, where the controller and cards are located. However, with this migration, the equipment was used to cutover DCS hardware from field cabinets and junction boxes outside.

This migration was safely completed in a classified area utilizing hot work permits. The project utilized 5 independent racks of TEMPUS stacks to cutover signals across 11 cabinets and junction boxes out in the field. In addition, configurable instruments were modified from DE to HART throughout the migration..

Kingsville, Texas

FRAC Honeywell HPM to DeltaV Migration

Across multiple marshalling cabinets, TEMPUS was used to cutover signals from a Honeywell HPM to DelatV Charms RIO. The congested space required some careful planning to move the wiring from the existing marshalling to new marshalling terminals in the same cabinet that are pre-wired to home run cables.

Kingsville, Texas

Trona mine processing of soda ash & sodium bicarbonate

At the Trona mine, an obsolete Measurex and outdated controlLogix controller was migrated completely online utilizing TEMPUS. These control cabinets had a tangled mix of relays, jumpers, and direct wiring with no marshalling terminals. Utilizing TEMPUS technology, our team was able to cutover the control to the new Siemens S7 system online. This cutover included 5 I/O cabinets in two MCCs with no additional floor space required as all the new components were retrofitted in the existing cabinets.

Rock Springs, Wyoming

Heat exchanger system

At this Oil Sands facility, three different control system platforms were migrated to a consolidated DeltaV platform. This particular area of the plant is used for hot water, flushing, and freeze protection which are essential, even during a total plant outage. An online cutover was the only option and TEMPUS was the perfect solution. Using this technology, CIMA+ was able to cutover the control of multiple obsolete platforms to a consolidated DeltaV DCS. Our team completed this project as a turnkey model responsible for everything from the study to the design, procurement, construction, commissioning and closeout.

Fort McMurray, Alberta

Centrifuge control

TEMPUS was utilized to cutover a fast acting 500 HP centrifuge. This centrifuge is used for separating minerals and solids from a bitumen stream to prepare it for upgrading. This centrifuge was migrated online with no loss of signal while plant operations maintained control in auto mode with very little interaction throughout the cutover process.

Fort McMurray, Alberta

Pump station migration

For this pipeline pumping station, TEMPUS was utilized to migrate multiple systems to a new M580 platform. CIMA+ worked as a system integrator and owners engineer while executing the online cutover in multiple cabinets.

Fox Creek, Alberta

Innovation Awards

TEMPUS has been recognized for its innovation and proven technology…