The G.E. Booth Wastewater Treatment Plant project was large and complex, with multiple phases, evolving requirements and aggressive timelines. Our team met these challenges with a collaborative mindset and help from virtual reality (VR).

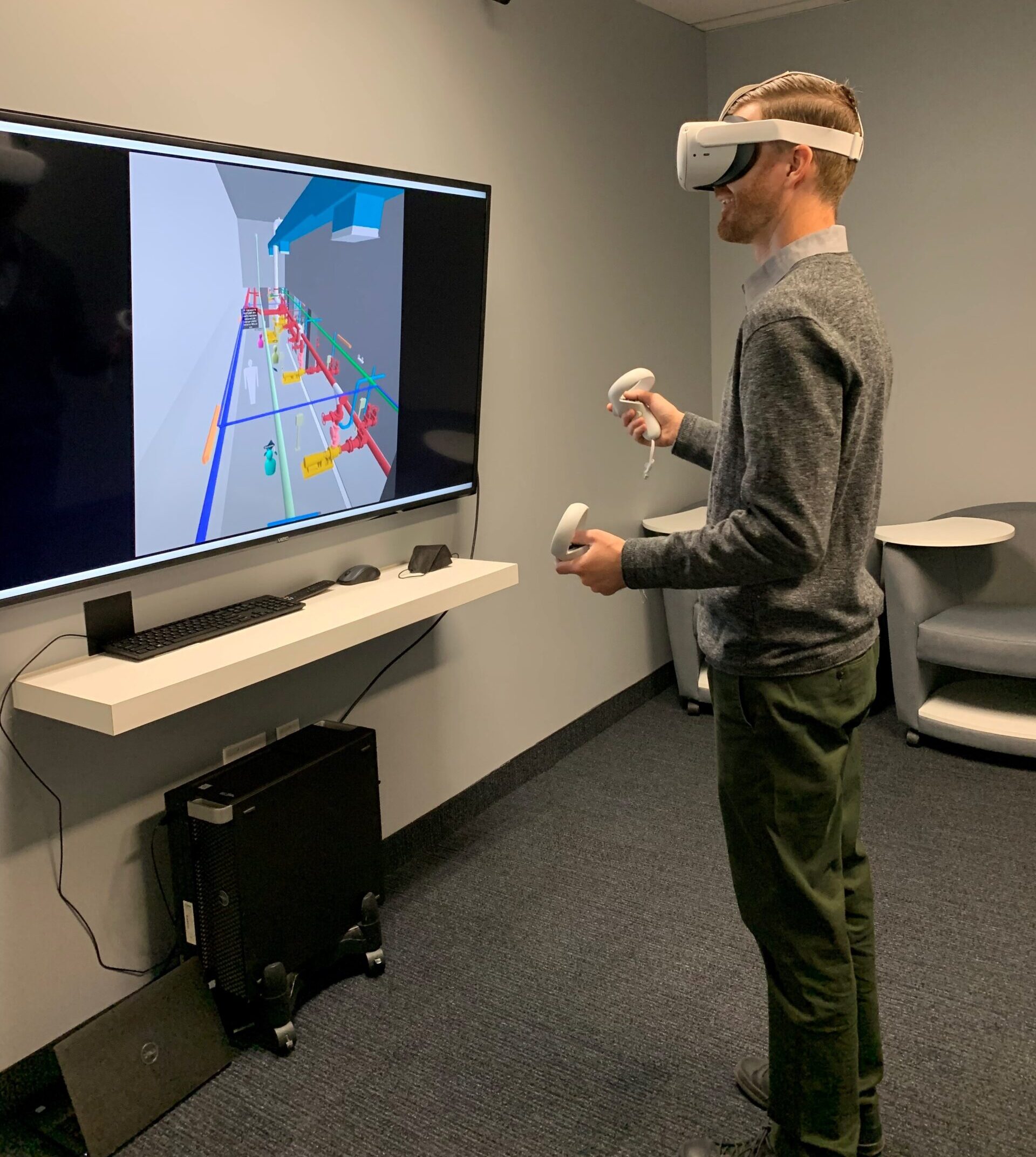

It was the biggest project our Toronto-based project manager Matt Woodbeck had tackled in his career, so far. Matt says the use of VR technology vastly improved the design review experience for the team at the wastewater treatment plant.

“It helped build trust, credibility, and connection between us, our engineers, and the client because they could really see what we had planned,” says Matt.

But the path wasn’t an easy one. The demanding, three-year design phase posed unique challenges that pushed our team to rethink the way we undertake the design process.

Complex wastewater treatment project with short timelines

The G.E. Booth Wastewater Treatment Plant is among the largest in Canada, and one of two lake-based plants serving over 1.5 million people in the Region of Peel.

The plant is comprised of three parallel conventional activated sludge facilities, and one of those – Plant 1 – is at the end of its useful life. The Region of Peel chose CIMA+ to replace it with a modern facility that would take it into the future.

The project needed to move quickly in anticipation of the area’s population growth. This required our team to stay one step ahead of the work, locking in future contracts while still working on the current one.

“Working collaboratively with the owner, operations staff, and our internal design team and sub-consultants to ensure we made the right decisions for everyone involved was really important for the job,” says Matt.

Site preparations for New Plant 1

An evolving scope of work

A new residential development planned on the site of a former coal-fired power plant located adjacent to the site added new requirements to the design. This development will bring 20,000 residents and 9,000 jobs to the area, making issues like odour, aesthetics, and construction noise important considerations in planning for the new wastewater treatment facility.

“The scope basically doubled in size in terms of what we were designing and building. And a lot of those changes happened while we were designing,” recalls Matt.

Site constraints pose challenges

Plant 1 is a small portion of a much larger facility, and our team had limited space to work with. “We had to design to maximize treatment capacity within a constrained site that can’t really expand,” explains Matt.

That presented both design and construction challenges. Along with that, construction couldn’t interfere with the existing plant – the old wastewater treatment plant must remain operational as the new one is being built.

Virtual reality tour brings design details to life

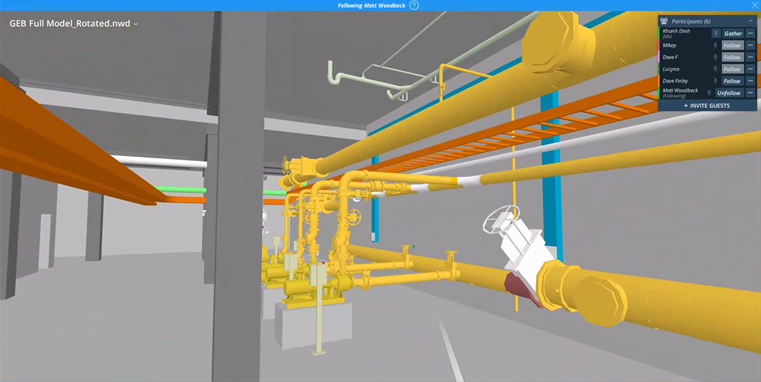

Our final set of design drawings includes almost 800 sheets – significantly larger than what a typical project would require. To give the plant owner and operations staff a better idea of what the design really entailed, our team opted to use VR headsets during key review workshops.

While we often use 3D fly-throughs to give clients a birds-eye view of a design, it’s not as immersive as the VR experience.

“The audience member still doesn’t have any control. They’re watching but they’re not interacting,” says Matt. “This was a way that they could interact with what we designed.”

VR in engineering helps meet clients where they are

With the VR headsets, the client team could virtually walk inside the new facility and see every key detail up close, making it easier for them to decide what they liked and what could be improved.

“The operators’ jobs are to be the boots on the ground seeing and operating things in real life,” says Matt. “Being able to put on the headsets allowed them to basically step into that huge set of drawings, instead of trying to figure out a way to digest that massive amount of information.”

With virtual reality, design review takes hours, not months

With the level of detail involved, Matt estimates it would normally have taken reviewers two or three months to look at the Plant 1 drawings, analyze the design, and provide feedback. The virtual reality tour enabled them to complete much of this task in only eight hours.

“It took that months-long review process and we were able to compress it down into two, half-day workshops. Everyone was able to walk away from it saying, ‘Okay, I really feel like I’m part of this project now.’”

Screenshot from model review

Building trust and strengthening relationships

Up until the final design review, Matt felt the 3D models weren’t communicating the ideas clearly enough for the client to really connect with the design.

“We could just tell, trying to walk them through that 3D model, they felt like outsiders. They didn’t feel that connection to what was there,” says Matt. “But the VR tour changed that. They got excited, and could really see the value.”

A better, safer wastewater treatment plant design

Since the plant owners and operators were able to walk through each area, they were better able to plan the interfaces. They could also easily flag potential issues – even small things like a piece of equipment that was located too high off the ground.

Catching these details in the design phase meant designing a safer plant for everyone, including for servicing and operations personnel.

“The operations staff brought in the actual people that do the work, who service the pumps and change out the valves and operate the gates, and we had good, focused discussions,” says Matt.

“It was about making small adjustments that can improve operations and safety for decades to come.”

Future New Plant 1

Exploring new opportunities for innovation

With design for Plant 1 complete, the four-year construction phase is scheduled to start in 2022.

It’s been the most challenging project Matt has ever worked on, and one made even more memorable by using VR to help simplify the complex and bring this design phase to a successful conclusion.

“It was a really rewarding experience,” says Matt. “It was a two-year effort going into the biggest project most of us had ever touched, and that was a pretty significant milestone for us to show it off and prove to the owner that we were on the right track and were close to the finish line.”

Along with augmented reality (AR), which allows us to layer the designed world on top of the real world, our teams are already investigating new ways to use VR to enhance the client experience in the future.

Curious about innovation at CIMA+? Stay tuned for more posts about how we’re working to serve our clients better!