In-depth experience with the various survey tools and technologies available on the market.

We offer high-quality survey services, backed by our knowledge of potential issues relative to the design and execution of engineering projects across our various areas of expertise. Our vast experience allows us to select the digital survey equipment and technologies that are best-suited to the client’s context and needs. From the survey of the existing situation to simulation of major maintenance (shutdown), solutions are gathered and incorporated into your work flow with a view to optimize your investment and achieve enhanced control of all parameters.

Analysis of verticality, flatness and deformation

With the high capture speed of the 3D scanner, it is possible to capture the existing condition of an infrastructure asset at a rate of millions of points per second, and to carry out a facade deformation or slab flatness analysis by generating a colour-gradient image to facilitate interpretation of the data.

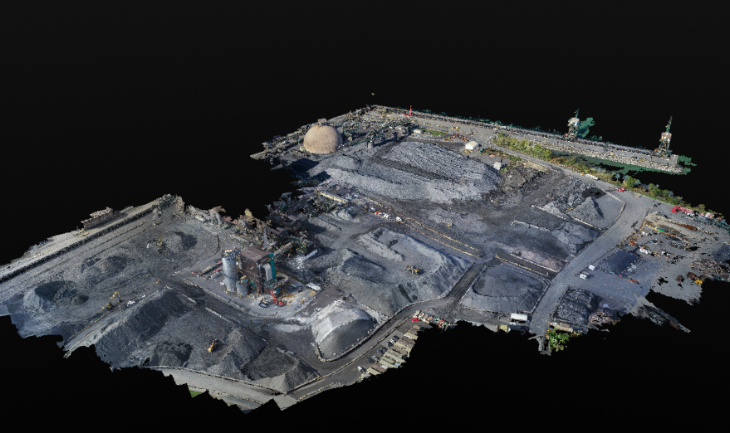

Volumetric calculations

Volumetry is the measurement of a space or element in three dimensions. We have the ability to precisely calculate the volume of a tract of land based on a three-dimensional topographic survey (photogrammetry, topographic survey, GPS survey, etc.). This allows us to generate a digital terrain model that takes into account the volume, the spreading of the material and the slope.

Data extraction and 2D drawing

Using the thousands of points captured by a 3D scanner or drone during a survey, the information required to prepare drawings of the existing conditions can be extracted by means of various tools designed to optimize the use of this information. The files that are obtained can then be input directly into the CAD software for data extraction and the production of drawings.

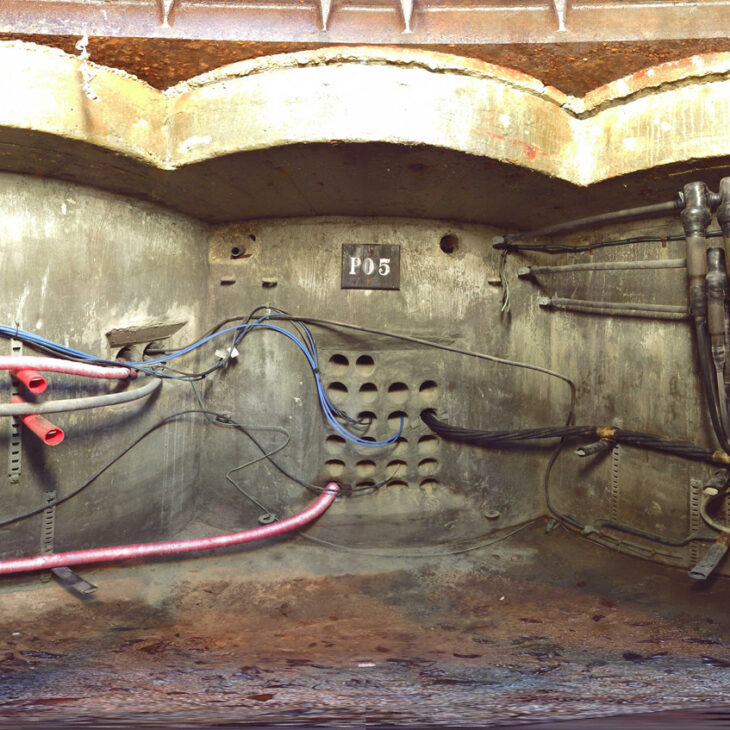

Inspection of confined spaces

Using specialized remote-controlled equipment, it is possible to capture the existing conditions in confined spaces and carry out surveys efficiently and safely. By capturing LiHDR 360 images with millimetre-level precision, we can produce a reliable portrait of all visible components inside the confined space in just minutes.

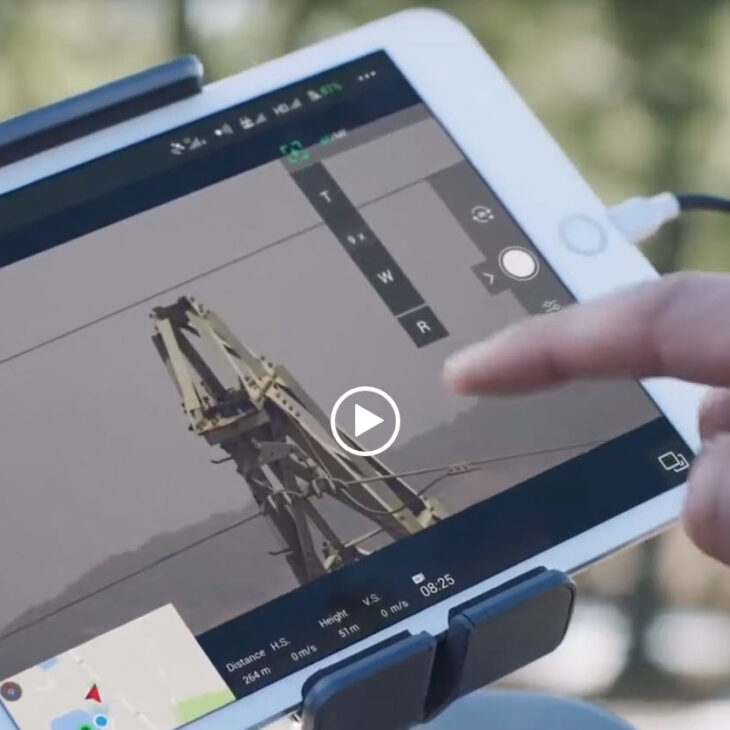

Infrastructure inspection

Using drones and high-precision sensors, we are able to capture the existing conditions of infrastructure assets and conduct surveys efficiently and safely. Capturing high-definition images allows for the generation of a 3D model or orthophotograph, and for rapid consultation of the photogrammetric survey.

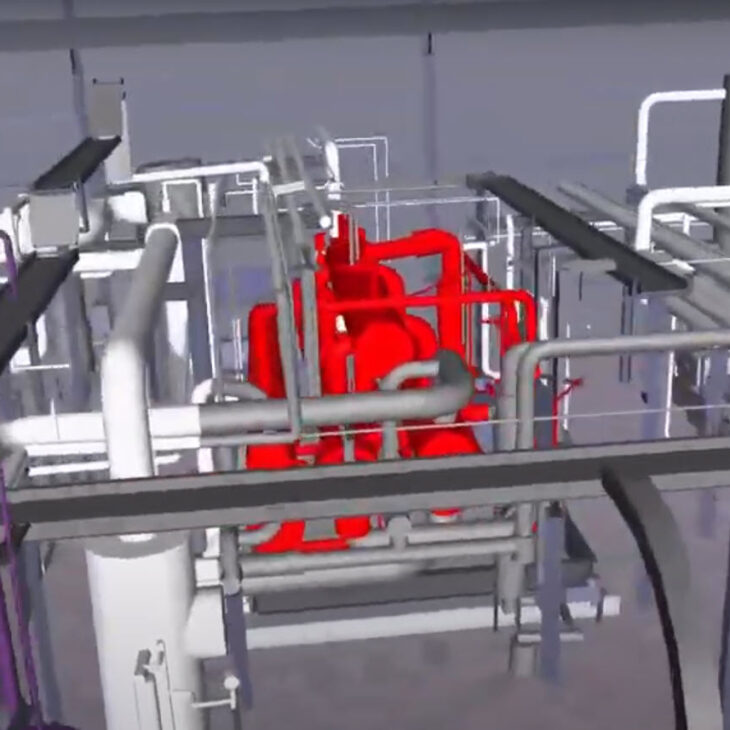

3D modeling

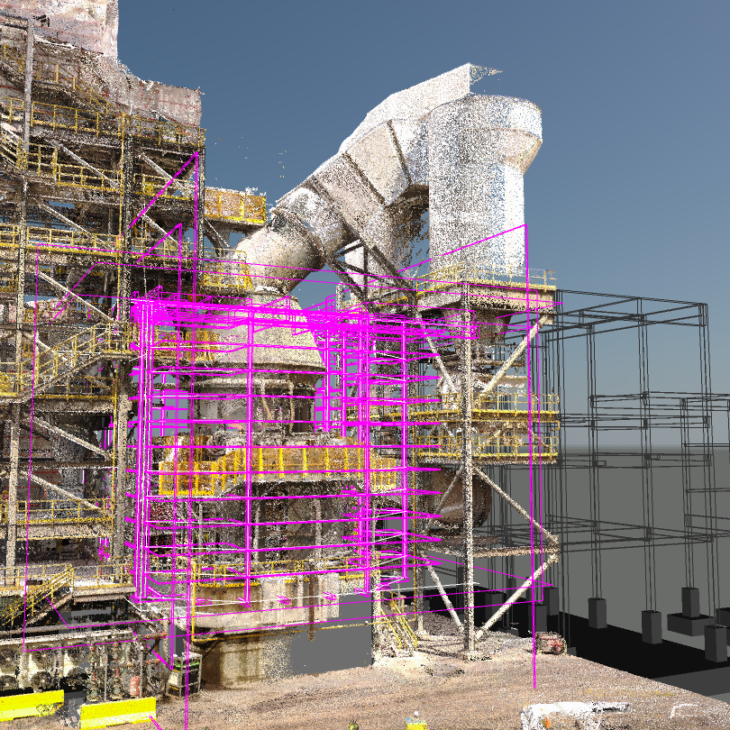

The point cloud that is obtained from a survey carried out using a 3D scanner or a drone can be input and used as a reference in CAD software packages, such as AutoCAD, Revit, Civil 3D, Inventor, 3DsMax, Infraworks, Navisworks, Sketchup, Microstation, Bentley Descarte, CATIA and Solidwork. There are many tools available for extracting and optimizing the use of point cloud data. Over the years, our technicians have developed expertise in the use of these various programs, and can efficiently convert 3D surveys into a 3D CAD model to generate a digital twin for conducting virtual simulations.

Orthophotographs

This technique involves processing aerial photographs using powerful software to obtain a three-dimensional image and a to-scale photomap, while deriving various measurements. Drone aerial orthophotography has interesting applications in many sectors, including agriculture, archeology, architecture, etc., and in particular, urban planning, land-use planning or the environment, environmental impact studies, prevention plans, landscape analysis or the revision of land-use plans (LUP).

Site supervision and quality control

Based on a 3D survey conducted using a 3D scanner or a drone, depending on the requirements, monitoring and quality control of the existing structures or of the work performed can then be carried out, along with site supervision. This makes it possible to characterize and index the as-built drawings over a given period and monitor the evolution of the site.

3D virtual visit

Using virtual reality (VR) technology, it is possible to simulate a site visit remotely, either in 3D or as a 360-degree view. The image representing the site being visited changes dynamically in response to the user's instructions. This technique makes it possible to visit buildings, industrial sites, confined spaces, museums or tourist sites, heritage buildings, entire cities and buildings for sale or rent, without having to travel to them.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Lorem amet malesuada vel.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fringilla ultricies purus ut sit nunc elit nec risus. Elit purus est at elit sed tristique congue.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Velit ultrices lectus quis leo lacus quis.

Mattis eros turpis pulvinar suspendisse vivamus varius venenatis elit. Sed habitant vulputate in sit cursus egestas ut. Massa tincidunt

fermentum vitae cursus. Odio quis in rhoncus quis pharetra.

Aliquet cras viverra maecenas diam iaculis sit amet donec. Elit, dignissim ultrices tortor turpis amet tellus ullamcorper diam. Vivamus

blandit quis aliquam ac. Bibendum pharetra massa vitae sodales eu gravida viverra diam, in. Eleifend.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Velit ultrices lectus quis leo lacus quis.

Mattis eros turpis pulvinar suspendisse vivamus varius venenatis elit. Sed habitant vulputate in sit cursus egestas ut. Massa tincidunt

fermentum vitae cursus. Odio quis in rhoncus quis pharetra.

Aliquet cras viverra maecenas diam iaculis sit amet donec. Elit, dignissim ultrices tortor turpis amet tellus ullamcorper diam. Vivamus

blandit quis aliquam ac. Bibendum pharetra massa vitae sodales eu gravida viverra diam, in. Eleifend.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Velit ultrices lectus quis leo lacus quis.

Mattis eros turpis pulvinar suspendisse vivamus varius venenatis elit. Sed habitant vulputate in sit cursus egestas ut. Massa tincidunt

fermentum vitae cursus. Odio quis in rhoncus quis pharetra.

Aliquet cras viverra maecenas diam iaculis sit amet donec. Elit, dignissim ultrices tortor turpis amet tellus ullamcorper diam. Vivamus

blandit quis aliquam ac. Bibendum pharetra massa vitae sodales eu gravida viverra diam, in. Eleifend.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Velit ultrices lectus quis leo lacus quis.

Mattis eros turpis pulvinar suspendisse vivamus varius venenatis elit. Sed habitant vulputate in sit cursus egestas ut. Massa tincidunt

fermentum vitae cursus. Odio quis in rhoncus quis pharetra.

Aliquet cras viverra maecenas diam iaculis sit amet donec. Elit, dignissim ultrices tortor turpis amet tellus ullamcorper diam. Vivamus

blandit quis aliquam ac. Bibendum pharetra massa vitae sodales eu gravida viverra diam, in. Eleifend.

News and blog posts

Les logiciels de CAO et les nuages de points

Atwater water treatment plant

Ville de Montréal needed to expand the offices and the employee parking area at the Atwater water treatment plant. This project required surveying work on a large scale, given...

Pavement condition assessment

CIMA+ used a drone to conduct a survey in order to generate a high-definition orthophotograph for the purpose of analyzing the condition of the pavement and quantifying the damage....

Simulation of the removal of industrial equipment at AkzoNobel

AkzoNobel, a paint and chemical products company, needed to remove a piece of equipment from a very tight space. CIMA+ conducted a survey using a 3D scanner, created a...

Commission scolaire de Montréal (CSDM) Schools

The CSDM wanted to carry out an assessment of the condition of the walls of a number of schools in the region. Many of these schools are historic buildings,...

Digital twins for maintenance installation, Via Rail

In anticipation of making changes to its Montréal and Toronto maintenance centres, VIA Rail Canada wanted to conduct the 3D digitization and 3D modeling of a given section in...

Condition assessment of walls, L’Étincelle school

The architectural firm of Bertrand + Paquette was called upon to assess the condition of the walls of L’Étincelle school, a historic brick building with many bas-relief designs.

The...

Bridge and smokestack inspection

Smokestacks must undergo regular inspections. Traditionally, these visual inspections are conducted by workers who rappel down the wall, which is a slow and tedious method. In order to speed...

Inspection of confined spaces, Horizon Utilities Project

This project involved 3D documentation of 237 underground electrical rooms in Hamilton and St. Catharines, Ontario with millimetre-level precision, making it possible to visualize their existing condition, take measurements,...

Lighting at Rio Tinto Iron and Titanium

The work to improve the site’s lighting system required preparation of an inventory of the various structures available to accommodate the lighting fixtures and estimation of the volume and...

Contact our team!

- By submitting this form, I agree to receive CIMA+’s email communications regarding news, updates and products.

- You may unsubscribe at any time. Please allow 10 business days to be removed from our mailing list.

- Please refer to our Privacy Policy on our website for more details.