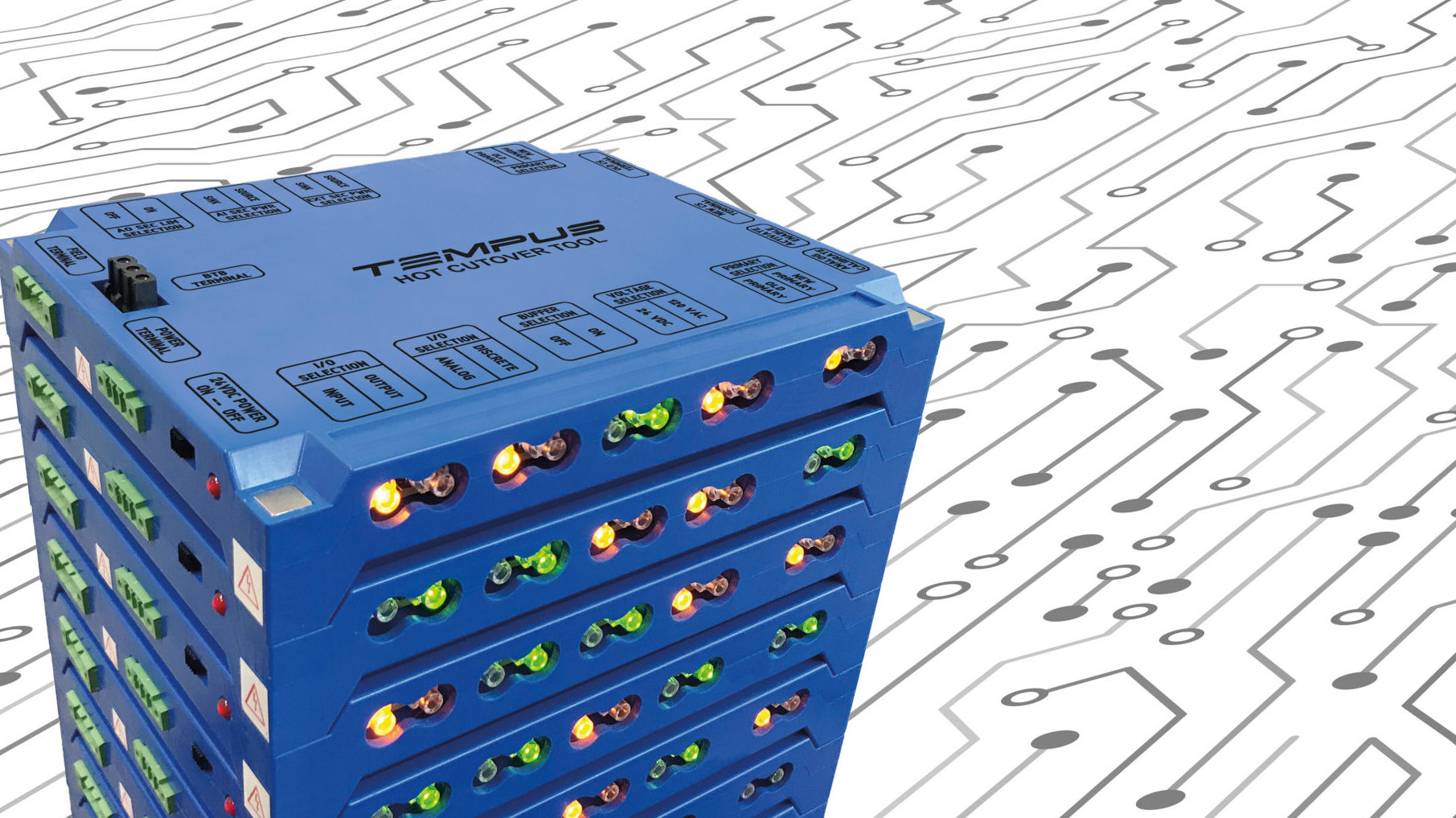

Developed by CIMA+, TEMPUS is the only tool on the market that allows you to replace aging control systems completely online, with zero interruption to your plant’s production – saving you time and money.

Control system migration at the push of a button

Combined with the expertise of the CIMA+ automation engineering team, TEMPUS eliminates shutdowns and simplifies the entire project. The risks and unknown factors surrounding the migration process are significantly reduced. This allows our team to carry out the whole project from concept to completion, including engineering, programming, procurement, construction, migration, and commissioning, without impacting production.

The perfect support solution

The CIMA+ team is comprised of TEMPUS experts who work closely with automation and instrumentation engineers and technicians. Together, they can manage an entire project or integrate TEMPUS with an existing project or system integrator, seamlessly adapting to your needs.

Discover our Tempus projects

Our teams have successfully completed hundreds of large-scale engineering projects.

Centrifuge control online migration (Fort McMurray, Alberta)

Complete control system migration using the TEMPUS Online Migration Tool to fully commission the new system online, while the existing control system remained operational, allowing for a seamless switchover...

Online migration of a plant heat exchanger control system (Fort McMurray, Alberta)

Using the CIMA+ TEMPUS Online Migration Tool, the control system swing over from three different systems to one DeltaV system was done online without interrupting the process. The process...

Implementing TEMPUS

Meet David Findlay, the brain behind TEMPUS

David is a Professional Technologist (P. Tech.) in the areas of electrical engineering and control system design. His focus has been on control system migrations of all kinds, including our in-house technology for online migrations. As a Partner at CIMA+, David is in charge of the Instrumentation and Control Department in Alberta. He has worked in the automation industry for over 17 years and contributed to a wide range of projects.

Email: TEMPUS@cima.ca

David Findlay, P. Tech. (Eng).

Senior Project Manager - Partner

Innovation Awards

TEMPUS has been recognized for its innovation and proven technology, which redefines control system migration.

2017 - Suncor extraction plant in Fort McMurray

CIMA+ won a Canadian Consulting Engineering Award in the Natural Resources, Mining, Industry, & Energy category.

2017 - Suncor extraction plant in Fort McMurray

CIMA+ won the Grand Prix du génie-conseil in the Industry category for its TEMPUS online migration tool.

2017 - Consulting Engineers of Alberta

CIMA+ received an Award of Excellence in the Natural Resources, Mining and Industry category for its unique online migration system, TEMPUS.

CIMA+: a one-stop solution for all your engineering needs

We are proud of our multidisciplinary approach. By offering you everything under one roof, you benefit from a simplified collaborative approach to deliver projects quickly and on time.

Contact our team!

- By submitting this form, I agree to receive CIMA+’s email communications regarding news, updates and products.

- You may unsubscribe at any time. Please allow 10 business days to be removed from our mailing list.

- Please refer to our Privacy Policy on our website for more details.