With its recent uptick in work, CIMA+ needed to optimize its concrete slab reinforcement process—and structural engineer and project manager François Leprince saw an opportunity for innovation.

“After working on the same task for three weeks,” says François, “I thought to myself…there’s got to be a more efficient way of getting this done.”

Aided by a small team and mentored by Julien Jean-Charland, innovation ambassador for the building sector, François reimagined the rebar specification process as a tool that integrates seamlessly into a 3D design environment.

With Junior BIM Coordinator Benjamin Dufour as programmer, François’s team developed, prototyped, beta-tested, and documented a fully integrated plugin for Autodesk Revit, the building information modelling software we use at CIMA+. The plugin streamlines the rebar specification process, optimizing our reinforcement drawing production.

We’re already leveraging this technology in most of our projects to simplify several workflows. Created in the spirit of true innovation, the plugin has transformed how we approach rebar specification, increasing our competitiveness and creating value for our clients.

A fully digital workflow

Under the old system, our engineers plotted rebar lengths and layouts on a planning sheet, then modelled them in Autodesk Revit. In this labour-intensive process, each rebar group had to be drawn to scale, and annotations and revisions were done by old-fashioned pencil and eraser. The final product could easily be misread, causing communication issues and delays further down the pipeline.

The new plugin completely bypasses the need to specify reinforcement details by hand: all annotations can be made and corrected in Autodesk Revit. And for anyone who prefers to make revisions the old-fashioned way, the plugin can even be used to input handwritten notes.

Automatic calculations

Once the designer inputs their initial specifications, the plugin automatically generates an Excel spreadsheet listing all the rebar bundles required for each slab. This at-a-glance table simplifies cost estimation and facilitates the peer-review process, letting colleagues easily compare specified quantities to initial project estimates. It’s even possible to analyze specifications by sector or direction.

A streamlined verification process

Traditionally, a modeller painstakingly integrated the finalized handwritten annotations into the 3D model. This process required the engineer to verify that the specifications matched the original calculations and correct any errors, while yet another colleague had to ensure everything still aligned with the original design intent.

With the plugin, annotations can now be verified directly by a colleague for code compliance. Once the plans are approved, the modeller integrates the annotations into the master model or simply prints the rebar model plans, significantly reducing the risk of error due to manipulation. The engineer remains entirely in control of the final product.

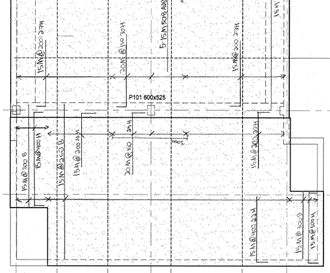

A planning sheet created using the old system

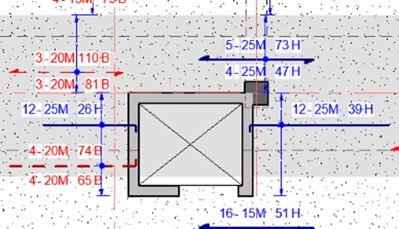

Specifications made with the plugin—legible, colour-coded, and easy to update

A concrete slab for which the rebars have been specified with the new plugin.

Easy implementation

As part of the software development process, François created a training manual to ease the transition to the new tool. But the plugin has been straightforward for our engineers to adopt—in fact, it took only a single hour of training for one of our designers to master the new workflow.

Most of our design teams are now working with the plugin. At the time of writing, it’s been used to create reinforcement drawings for more than 90,000 m² of structural slabs.

Proven efficiency

To quantify the new workflow’s efficiency, we tested it out when designing a hospital pavilion at the Enfant-Jésus site in Quebec City. We measured the time required to specify reinforcement for a single slab using both the traditional method and the new.

Using the conventional process, our design engineer needed one week to specify reinforcement in a single direction for the first of the slab’s four quadrants. But with the plugin, she completed the rest of the first quadrant and the three other quadrants in both directions…in the same amount of time! What’s more, everything was approved without a constant back-and-forth with the modelling team.

Says François, “With the plugin, our work process for creating reinforcement drawings is four times faster, while the overall reinforcement design process is 30% more efficient.”

Greater flexibility

To stay competitive, engineering firms must be constantly on the lookout for ways to optimize our processes. By streamlining reinforcement drawing production, our new Autodesk Revit plugin gives CIMA+’s engineers the flexibility to complete fast-track projects quickly and efficiently without sacrificing quality. The plugin also lets us shake up other work processes, further meeting our customers’ needs.

Curious about innovation at CIMA+? Stay tuned for more posts about how we’re working to serve our clients better!