A high percentage of fines were regularly observed in the ore fed to the grinding circuit. Already at the desired size, these particles simply clogged up the circuit.

CIMA+ proposed to prescreen the -1 mm material prior to milling. This has reduced the number of milling lines, enabling the circuit to operate at full capacity.

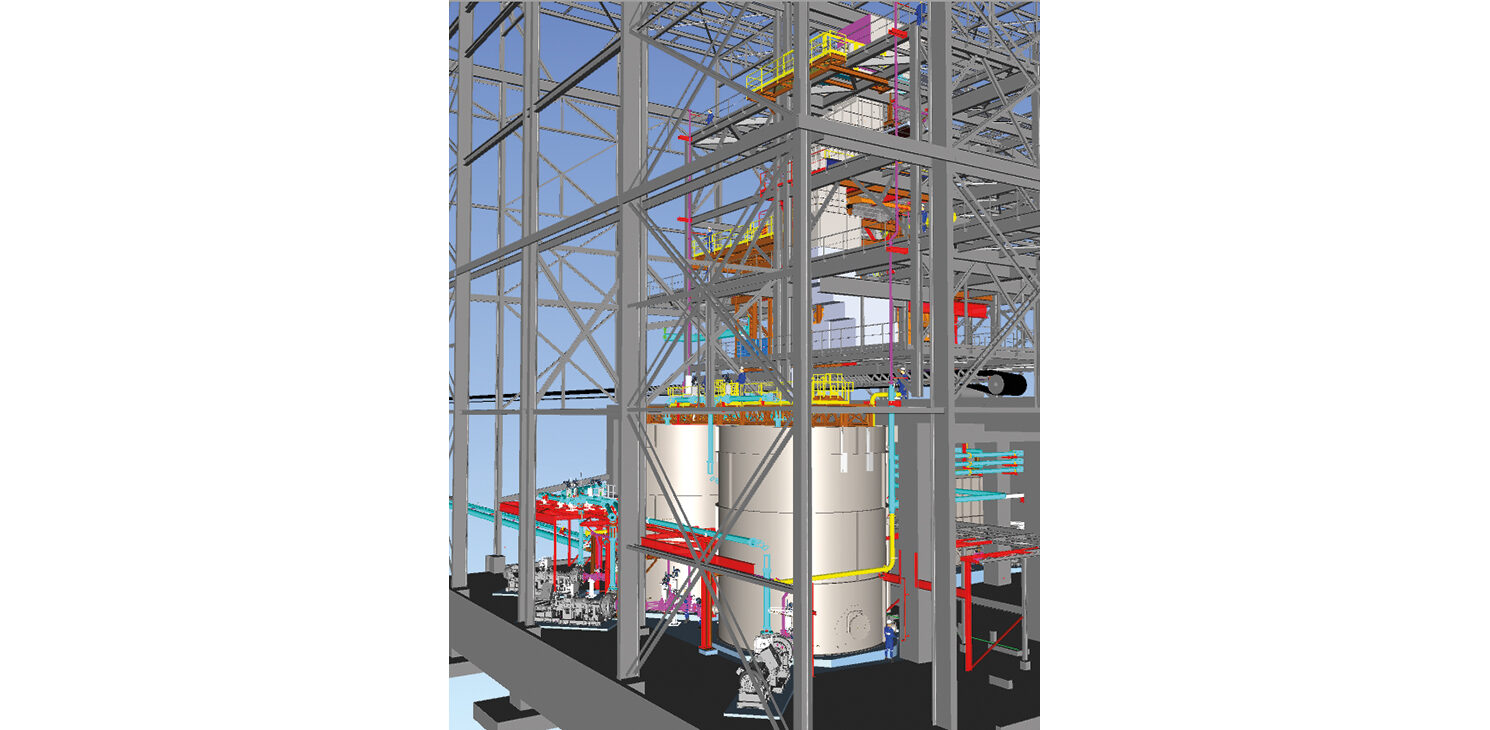

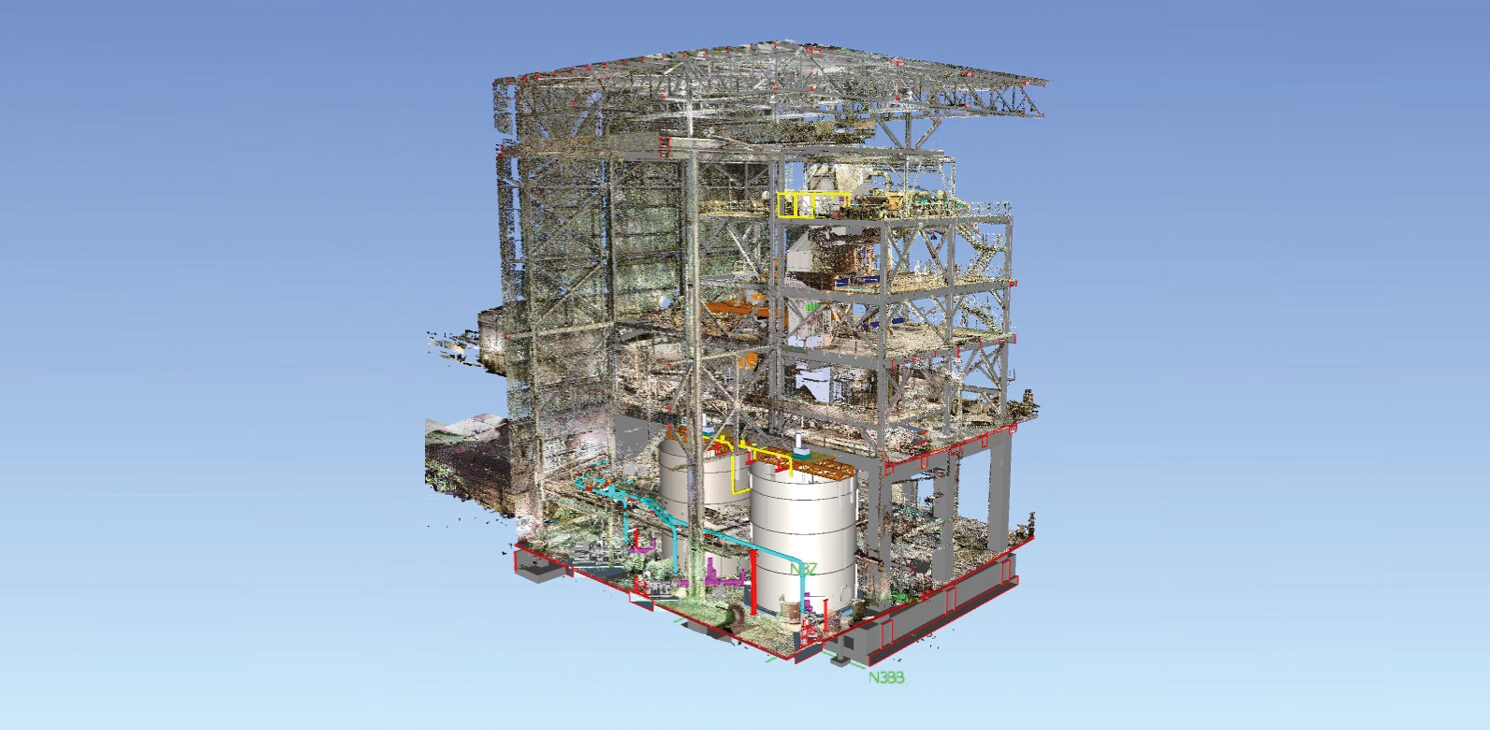

CIMA+ has designed a system to divert the fines directly into the gravity concentration circuit, bypassing the milling circuit. This bypass system ties into the existing system through a new spiral feed pump box. This box is fed by the fines and the milling circuit product. The pump box output feeds the existing gravity circuit. As a result, the prescreening circuit can be bypassed when required, for either operation or maintenance purposes. Furthermore, the design makes it easy to supervise operations and maintenance.

Sustainable development

Prescreening a sizable proportion of fines and bypassing the milling circuit significantly reduced energy consumption. Also, the fine bypass system reduces the production of this type of particle, which is particularly beneficial to the dewatering and tailings management circuits.

Innovation

Due to limited available footprint, conventional means of feed transfer from the spiral feed pump box to the gravity concentration circuit could not be used. A new feed distribution system had to be designed to transfer the slurry through two individual loops with partial recirculation back to the pump box. The loops use control strategies to ensure homogenous feed distribution and prevent sedimentation in the pipeline. Special chutes had to be designed to feed the new prescreening vibrating screen.