CIMA+ was first called in on an emergency basis when the overflow from the tanks and the transfer boxes on the plant floor was at risk of flowing outside the building. Our team quickly carried out a complete analysis of the process and operating data of the plant, interviewed operators on-site and reviewed a substantial number of drawings and documents from the archives of the plant.

Sustainable solutions were proposed within only a few weeks.

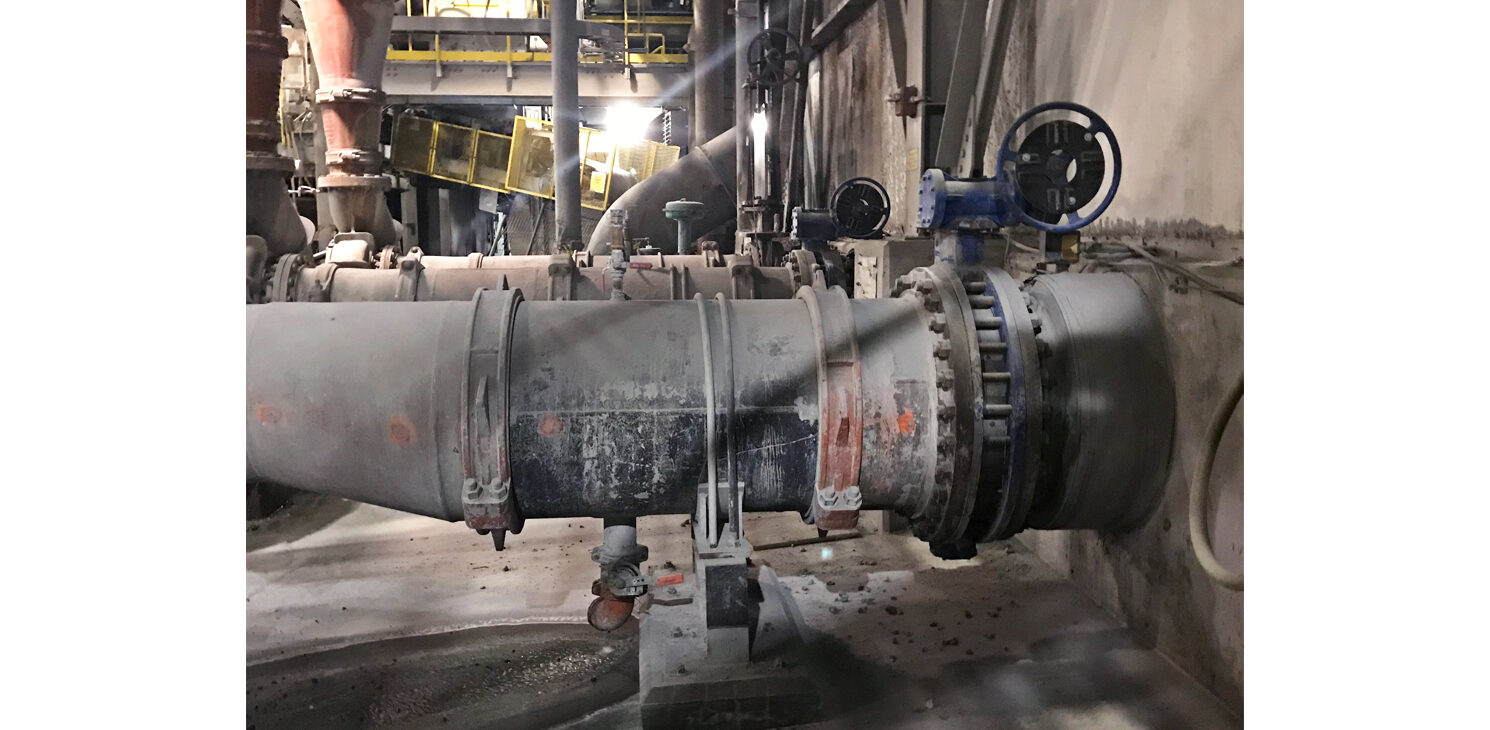

The solutions provided included: installing automatic valves at the outlet of tanks, increasing the volume of the tanks, the temporary use of tank retention dikes and installing emergency pumping systems.

CIMA+, in collaboration with the client, carried out the detailed engineering after the optimal solution was selected.