The North Brampton reservoir and pumping station supply drinking water to pressure zones 6 and 7 of the Region’s water distribution system. The zones contain established residential and commercial areas as well as several areas identified for development. The two facilities were originally constructed in the 1980s and then expanded and upgraded over four decades, with the design of 2014 process upgrades and 2018 emergency switchgear upgrades completed by CIMA+. The 2018 emergency upgrades were based on a 2015 condition assessment of the pumping station that was also completed by CIMA+. The 2018 upgrades eliminated the risk of failure of obsolete switchgear technology.

In 2022, the Region retained CIMA+ to provide design and construction services for additional improvements at the pumping station that were recommended in the 2015 CIMA+ condition assessment. These upgrades will improve the operability and reliability of the pumping station and reservoir facility through further replacement of older non-redundant electrical equipment. The upgrades will include:

- New 27.6kV aerial cabling and related primary utility metering

- Two new 27.6kV-600V outdoor pad-mounted tamper-proof transformers

- New 600V secondary selective service entrance switchgear

- New 24VDC uninterruptible power supply system

- Replacement of the motor control centre

- Modifications and upgrades to the HVAC system in support of the new switchgear room

- Modification of the pumping station building to accommodate the new switchgear and electrical distribution equipment

- Site civil upgrades to support the new electrical equipment and outdoor substation

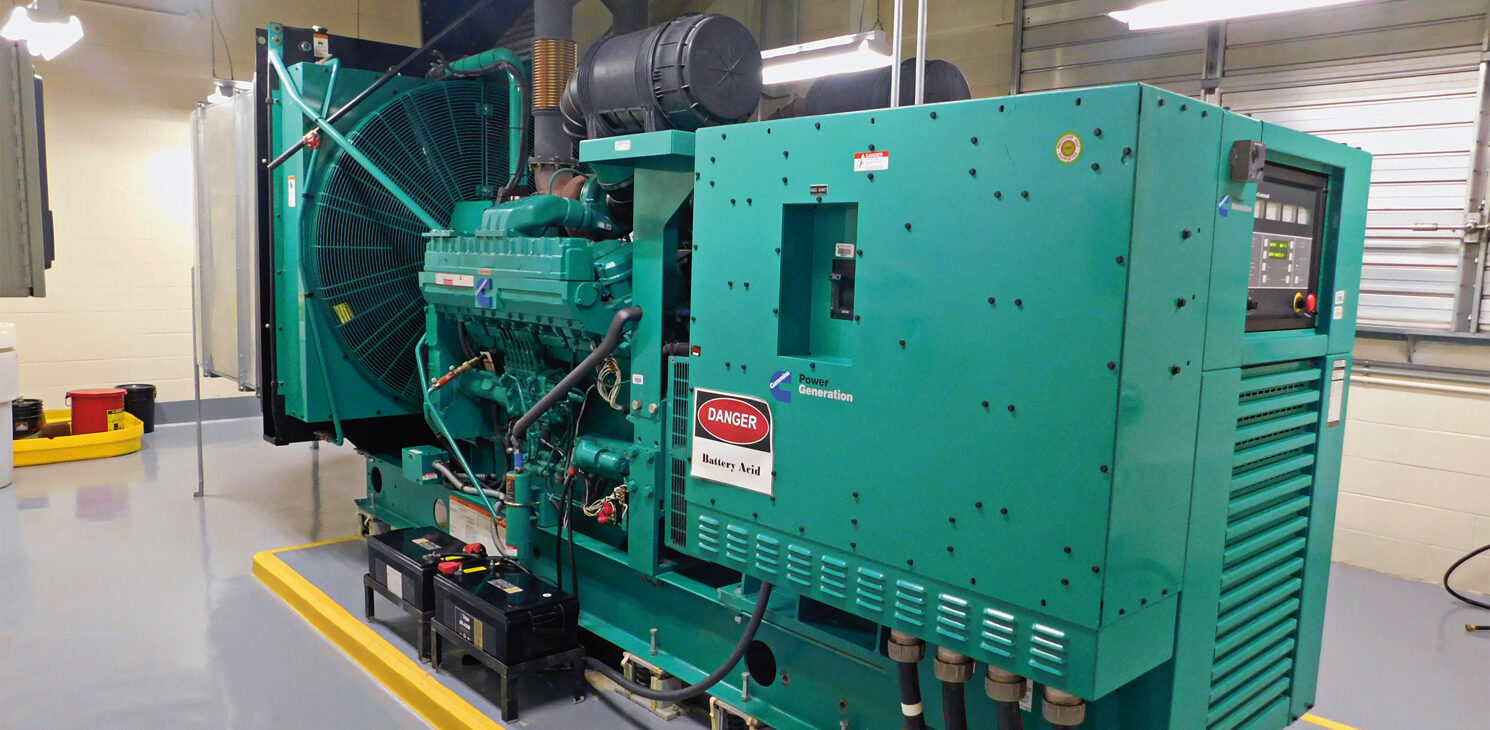

The switchgear is now consistent with other electrical systems at transmission pumping station facilities throughout the Region, with added protection relays, controls, and automation. The electrical upgrades also introduced redundancy in the utility power supply. Power is now fed from two separate transformers to main-tie-main switchgear, which provides greater reliability and allows for isolation of process equipment during maintenance. The new electrical distribution system includes enhanced emergency generation operation using an existing diesel standby unit, with the ability to operate in parallel with the utility source. The team at CIMA+ completed the Connection Impact Assessment (CIA) application required by the utility to facilitate parallel operation with the emergency generator.

Smart sequencing of upgrades for more efficient delivery of the project

The design team retained Alectra Utilities and Alectra Power Services on behalf of the Region to complete the aerial high-voltage upgrades in advance of the electrical upgrades at the station. The scope of work included prepurchase by the Region of the necessary transformers, which had a long production lead time. The design includes careful sequencing of the electrical work so that the replacement of the new transformers, switchgear and motor control centre can occur in parallel to limit shutdowns of critical process equipment.

Remote operation of switchgear for better monitoring and faster response to problems

The switchgear includes a new human-machine interface tied to the SCADA system that will allow Operations to locally or remotely operate the switchgear for power distribution and generator startups. This new functionality, which also allows for remote monitoring of alarms, will facilitate troubleshooting and early identification of problems.